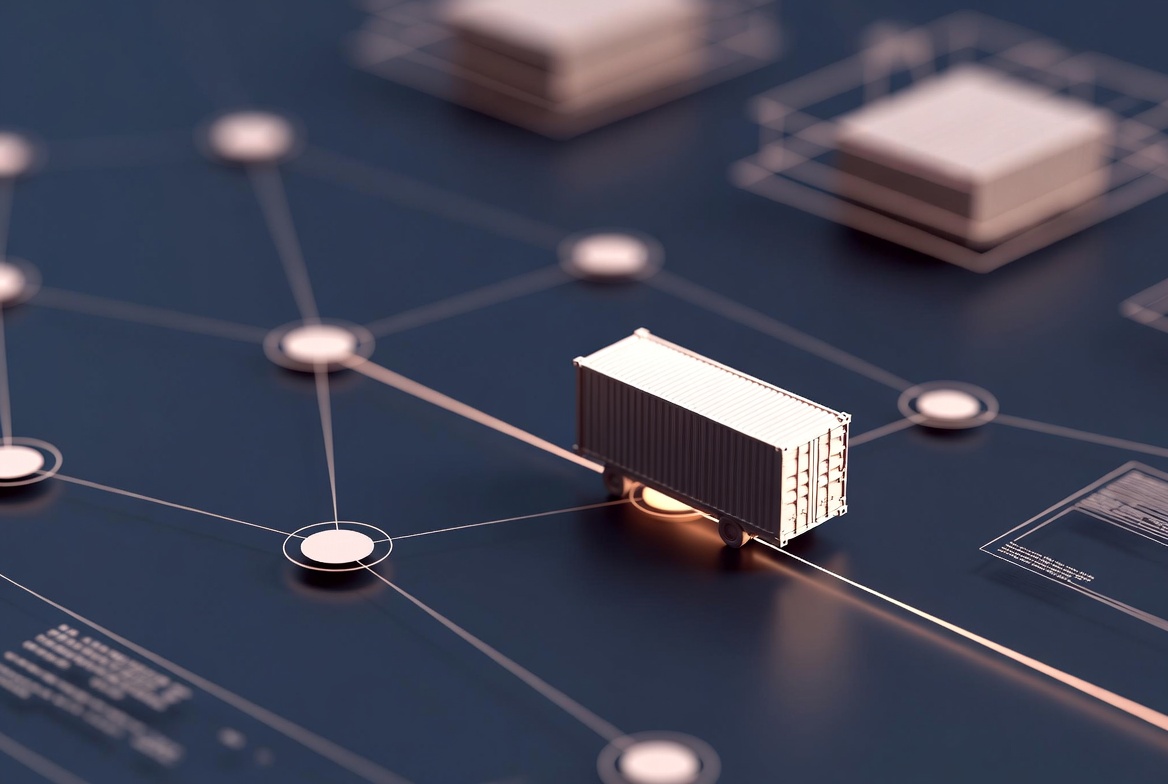

For freight forwarders and logistics teams, a central contradiction exists: physical cargo moves through a connected global network, but the data and tools managing it are isolated. This leads to operational friction—endless emails, missed updates, and reactive firefighting. A modern Logistics Management System (LMS) solves this not by being a better tracker, but by becoming a collaborative operating engine that redefines how logistics work is coordinated, executed, and optimized.

The Shift: Linear Communication to Networked Synchronization

The Problem: Traditional logistics coordination relies on linear, slow information handoffs (email, spreadsheets, calls). This creates delays, errors, and immense effort to get a single status update across multiple parties.

The Solution: A collaborative LMS creates a single, shared source of truth for each shipment. Authorized internal teams and external partners (carriers, brokers, agents) update status directly into a unified platform. This transforms sequential "notifications" into real-time state synchronization. Logistics digitization here means digitizing the collaborative relationship itself, eliminating the communication relay race.

Core Mechanism: Process Standardization & Unified Visibility

The Problem: Operations depend on individual expertise ("tribal knowledge"), making processes opaque, hard to scale, and impossible to measure for bottlenecks.

The Solution:

Process Standardization & Automation: The LMS codifies best practices into clear, automated workflows. Tasks are auto-assigned with deadlines, and the system enforces sequence, ensuring consistency and freeing staff from manual coordination.

End-to-End Milestone Visibility: True logistics visibility is more than tracking. It's the correlation of physical events with digital data (documents, responsibilities, time stamps) into a coherent business narrative. All stakeholders see the same story: "Cleared Customs → On Vessel → In Transit," enabling proactive management and building trust.

The Efficiency Outcome: How a Modern LMS Transforms Operations

This architectural shift delivers tangible efficiency by eliminating systemic waste:

Reduces Coordination Overhead: It drastically cuts the time spent searching for updates and chasing partners, allowing teams to focus on value-added tasks and exception management.

Enables Proactive Exception Management: Real-time transparency exposes delays immediately, often allowing for intervention before they escalate into costly disruptions.

Creates a Foundation for Data-Driven Optimization: Standardized processes generate structured data. This allows analysis of performance trends, bottleneck identification, and informed decision-making for continuous operational efficiency gains.

Supports Scalable Growth: The scalable cloud architecture and standardized digital workflow make onboarding new clients, partners, or trade lanes smoother and more controlled.

Conclusion: Redefining the Management Model

In essence, a collaborative LMS elevates a logistics provider from manually coordinating information about shipments to systematically orchestrating the supply chain. It replaces fragmented tools and ad-hoc communication with a unified operational layer designed for the complexity of modern, multi-party logistics. The result is a more resilient, transparent, and efficient operation capable of scaling with clarity.